Page 12 - Tcexpression2021 - Sept to Dec 2020

P. 12

Energy transition initiatives may reduce material Simple ABCD Model for Energy Transition:

requirement and complexity (from 10,000 moving

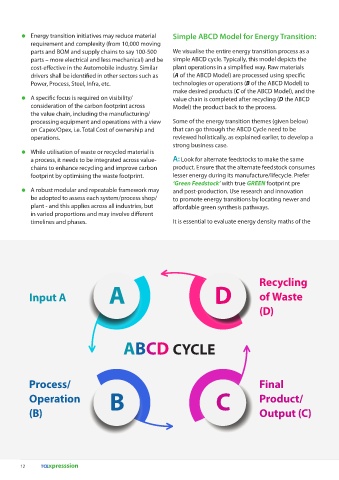

parts and BOM and supply chains to say 100-500 We visualise the entire energy transition process as a

parts – more electrical and less mechanical) and be simple ABCD cycle. Typically, this model depicts the

cost-effective in the Automobile industry. Similar plant operations in a simplified way. Raw materials

drivers shall be identified in other sectors such as (A of the ABCD Model) are processed using specific

Power, Process, Steel, Infra, etc. technologies or operations (B of the ABCD Model) to

make desired products (C of the ABCD Model), and the

A specific focus is required on visibility/ value chain is completed after recycling (D the ABCD

consideration of the carbon footprint across Model) the product back to the process.

the value chain, including the manufacturing/

processing equipment and operations with a view Some of the energy transition themes (given below)

on Capex/Opex, i.e. Total Cost of ownership and that can go through the ABCD Cycle need to be

operations. reviewed holistically, as explained earlier, to develop a

strong business case.

While utilisation of waste or recycled material is

a process, it needs to be integrated across value- A: Look for alternate feedstocks to make the same

chains to enhance recycling and improve carbon product. Ensure that the alternate feedstock consumes

footprint by optimising the waste footprint. lesser energy during its manufacture/lifecycle. Prefer

‘Green Feedstock’ with true GREEN footprint pre

A robust modular and repeatable framework may and post-production. Use research and innovation

be adopted to assess each system/process shop/ to promote energy transitions by locating newer and

plant - and this applies across all industries, but affordable green synthesis pathways.

in varied proportions and may involve different

timelines and phases. It is essential to evaluate energy density maths of the

A D Recycling

Input A of Waste

(D)

ABCD CYCLE

Process/ Final

Operation B C Product/

(B) Output (C)

12 TCExpresssion