Pipeline Intrusion Detection

Pipeline Intrusion Detection (PID) detects for any third party interference, malicious attempts and unauthorised excavation along buried pipeline which pose a major challenge. The pipelines often are routed through remote and hostile territories which run from a few to thousands of kilometers.

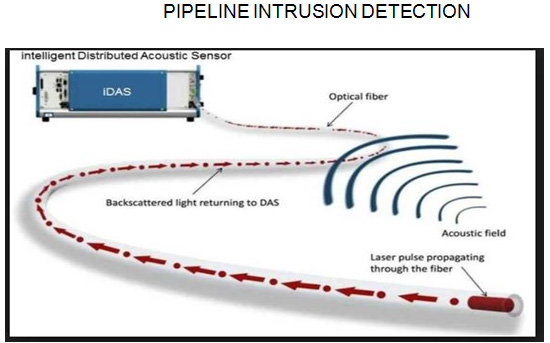

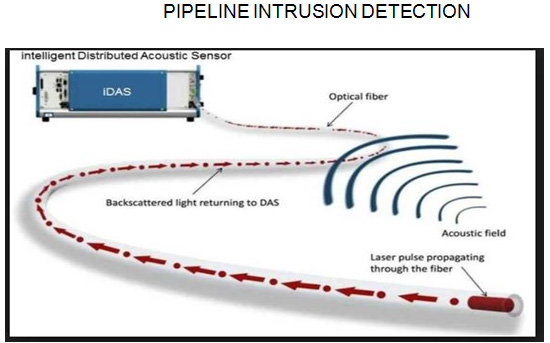

Generally buried pipelines, especially gas pipelines are identified by the warning signs and the rights-of-way marked above it. Nevertheless, during construction activities, the pipelines are sometimes damaged by third party, causing huge destruction and property loss. Such damages could be prevented by detecting the potentially hazardous equipment before the pipeline gets damaged. Using Optical Fibre Cable (OFC), that runs along the pipeline, the system is able to detect, locate and even identify any intrusion attempt accurately along the entire monitored length in real-time. This system works on the principle of Distributed Acoustic Sensing (DAS), where acoustic signals generated by intrusion activities are picked up by the optical probe as pulses and sent down the OFC.

The optical fibre cable is buried above the pipeline for Gas service and below the pipeline for liquid service. Under normal conditions, the light source sends the light pulses down the optical fibre and the light is reflected back to the source. During Construction, the equipment creates vibration in the ground causes compression of the soil. When close to the optical fibre, the vibrations and soil compression stress and/or bend the fibre, changing its light transmission and reflection properties. The light reflected back to the source detects the change. As the velocity of light in the fibre is known, the time of the reflected light pulse is a measure of the location of the equipment. The optical fibre returns to normal after the equipment leaves. Compared to mowing equipment and pedestrians, construction equipment being large have characteristic signal.

This system has its monitoring unit placed in the control room and requires no installation in the field besides the existing OFC. This enables a high rate of intrusion detection and also minimizes nuisance alarms using advanced signature analysis. Each type of intrusion has a distinct “acoustic signature” by which it can be uniquely identified and categorised into walking, manual digging, excavation, mechanical digging, and vehicle movement and so on. Uniform distributed fibre optic sensor results in maximum efficiency and higher safety for the pipeline. The pipeline intrusion detection system is designed for high risk pipelines carrying crude oil, gasoline, aviation fuel, chemicals, gas pipelines, underground power and drinking water to name a few.

OPTICAL FIBER SELECTION

The choice of the fibre in the cable and its environmental shielding are important factors in the selection of the optical fibre. The optical fibre should be sensitive to stress and vibrations. Environmentally, the cable must be impervious to water, non-electrically conducting (to avoid danger from lightning strike) and sensitive to abrasion (being chewed by rodents). At the same time the environmental sheath must not make the system insensitive to the vibrations and stresses to be measured.

OTHER APPLICATIONS

Based on the principle of DAS, the sensitivity and speed can cover distances upto a maximum of 50 km from each laser source. Continuous monitoring of the pipeline using optical fibre cable can guard against flow irregularities, leaks & Interference. Borders, Roads, Perimeters etc can also be monitored for activities which are unusual. Due to the harsh weather withstanding capability of fibre optic cable, real time monitoring of the oil well is also considered for information on the condition of the well. With suitable analysis software, the status of the Optical fibre cable can be remotely monitored.

TCE has experience in engineering a number of pipeline projects in Chemical & Industrial Business Units. Application of this technique can be explored for implementation based on the criticality and economic viability.