Carbon Capture, Utilisation, and Storage (CCUS) in India – An Overview

Introduction

Carbon capture and utilisation (CCU) covers a variety of technologies designed to capture carbon dioxide (CO2) emitted from industrial processes and other sources, transforming it into valuable products. The application of CCU technologies holds promise for substantial reductions in greenhouse gas emissions and the generation of novel economic opportunities.

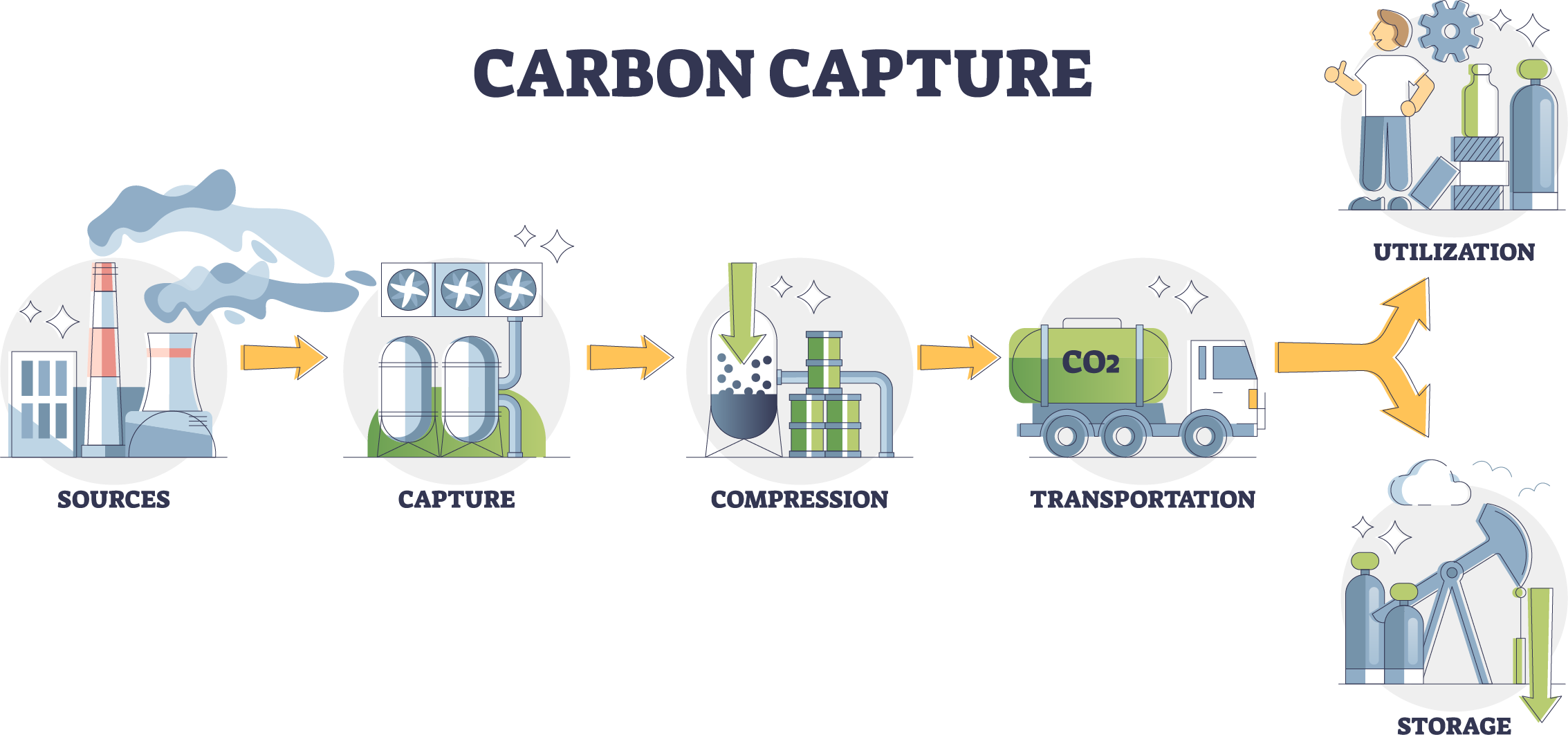

Figure 1 depicts the representation of the CO2 value chain, which includes sources, capture, compression, transportation storage and applications.

Fig-1: Schematic of CCUS

Currently, India relies predominantly on fossil fuels for its energy needs. In 2022, fossil fuels constituted 88% of India’s primary energy consumption, with 77% of electricity generated from fossil fuels. Among these, coal contributed 72.5%, natural gas 4.2%, and oil 0.3%. Given the widespread use of fossil fuels in both industrial processes and energy generation, decarbonising the industrial sector poses an impressive challenge, necessitating the adoption of Carbon Capture Utilization and Storage (CCUS).

India’s gross emissions will likely persist at around 1.4 GtCO₂e annually till 2050, particularly from the hard-to-abate sectors, i.e., agriculture, cement, chemicals and steel. CCUS can help reduce these emissions by 329 MtCO₂e annually by 2050 and 403 MtCO₂e by 2070.[1]

[1] Decarbonizing India – Charting a pathway for sustainable growth by McKinsey Sustainability

CO2 Capture Technologies

CO2 can be captured as mentioned below:[1]

- Post-combustion method: In this method, CO2 is removed from gases emanating from burning fossil fuels, agricultural waste, biomass, or chemical processes.

- Pre-combustion method: In this method, fossil fuel is converted into a blend of CO2 and hydrogen, where CO2 is extracted and stored, whereas hydrogen can be used as a low-carbon fuel in industries, transportation, etc.

- Oxyfuel: This technology produces CO2 and steam by burning fossil fuels with pure oxygen.

New or existing plants not built with CCS technology, the post-combustion and oxyfuel equipment can be fitted easily. For example, a gas-fired power plant can be retrofitted with CCS to reduce carbon emissions. The pre-combustion method requires significant plant modifications and is mainly suited to new setups.

Types of CCU Technologies

CCU technologies can be classified into three main categories, as given below[2].

Direct utilisation:

This involves using CO2 directly in products or processes, such as food and beverages, enhanced oil recovery, and building materials. This is the most mature CCU technology so far. CO2 is already used in a variety of products and processes, including:

- Food and beverages: CO2 is used in carbonated drinks, such as soda and beer, and food packaging.

- Enhanced oil recovery (EOR): CO2 is injected into oil fields to help extract more oil.

- Building materials: CO2 can make concrete and other materials more robust and durable.

Indirect utilisation (Chemical conversion):

This involves converting CO2 into chemicals like fuels, plastics, and fertilisers. Chemical conversion of CO2 is a rapidly developing field. Several companies are developing technologies to convert CO2 into chemicals, such as fuels, plastics, and fertilisers. Some examples of chemical conversion of CO2 are as follows:

- Fuels: CO2 can be converted into synthetic fuels, such as methane and methanol, which can be used in transportation and other applications.

- Plastics: CO2 can be converted into plastics, such as polycarbonates and polyurethanes.

- Fertilisers: CO2 can produce urea, syn gas, and other fertilisers.

Biological conversion:

In this process, microorganisms convert CO2 into products, such as biofuels, bioplastics, and animal feed. It is another rapidly developing field. Several companies are developing technologies to use microorganisms to convert CO2 into products, such as biofuels, bioplastics, and animal feed. Some examples of biological conversion of CO2 include:

- Biofuels: Algae and other microorganisms can produce biofuels from CO2.

- Bioplastics: Microorganisms can be used to produce bioplastics from CO2.

- Animal feed: Microorganisms can produce protein and other nutrients for animal feed from CO2.

CCUS Potential in India

India has significant potential for CCUS deployment, given its large number of coal-fired power plants (285 Nos as of 2022)[3] and growing industrial sector. The Government of India supports CCUS development, and several CCUS projects are currently underway in the country.

However, there are a number of challenges to deploying CCUS in India, including cost, lack of infrastructure, and public acceptance in spite of significant potential benefits.

Potential benefits of CCUS in India

The potential benefits of CCUS are:

- Reduced greenhouse gas emissions: CCUS can play a pivotal role in mitigating greenhouse gas emissions from various industrial processes and power generation, helping India achieve its emission reduction targets. Especially from sectors like cement, steel, and power, India can significantly contribute to global efforts in combating climate change by capturing and storing CO2.

- Job Creation and Economic Growth: The deployment of CCUS technologies can foster the growth of a new industry, creating job opportunities in research, development, and implementation of these technologies. Investments in CCUS projects can contribute to economic growth by establishing a green and innovative sector. CCU technologies can create new economic opportunities by developing new products and markets for CO2.

- Improve Energy Security by Reducing reliance on fossil fuels: India’s dependence on coal for energy security is well-documented. CCUS allows for the continued use of fossil fuels, such as coal and natural gas, while minimising their environmental impact, ensuring a more secure and reliable Energy Security. India’s dependence on coal for energy security is well-documented. CCUS allows for the continued use of fossil fuels, such as coal and natural gas, while minimising their environmental impact, ensuring a more secure and reliable energy supply.

- Technological Innovation: Embracing CCUS necessitates technological advancements, encouraging innovation and research in carbon capture and storage technologies. This innovation can have broader applications beyond CCUS, promoting a culture of technological development.

Current status of CCUS development in India

The Government of India has taken several steps to promote the development and deployment of CCUS technology. The MoPNG launched the National CCS Mission to support the development of pilot-scale CCUS projects in India. The Mission has also provided funding for research and development on CCUS technologies.

In 2022, NITI Aayog will release India’s Carbon Capture, Utilisation and Storage Policy Framework and deployment mechanism. The Framework outlines the Government’s vision for CCUS development in India and sets out several policy measures to promote the deployment of CCUS.

- The deployment of Carbon Capture, Utilisation, and Storage (CCUS) projects in India faces several challenges, reflecting the complex nature of integrating such technologies into the country’s industrial and energy landscape, and they are as mentioned below.

- Costs and Financing: The initial capital costs associated with implementing CCUS technologies can be significant. Securing financing for these projects may pose challenges, particularly in an economic context where cost-effectiveness is critical.

- Lack of Regulatory Framework: A robust regulatory framework specific to CCUS projects can help their development. Clear guidelines, standards, and incentives are necessary to encourage industry participation and compliance.

- Infrastructure Development: Establishing infrastructure for transporting and storing captured CO2 is a logistical challenge. Developing pipelines and storage facilities requires substantial investment and coordination among stakeholders.

- Technology Readiness: The maturity of CCUS technologies may be a limiting factor. Some technologies are still in the early stages of development, and their scalability and reliability need to be proven before widespread adoption.

- Integration with Existing Industries: Adapting CCUS technologies to existing industrial processes poses technical challenges. Integration with diverse industries, each with unique processes and emissions, requires careful planning and customisation.

- Awareness and Capacity Building: Limited awareness and understanding of CCUS technologies among policymakers, industry leaders, and the public can impede progress.

- Policy and Regulatory Uncertainty: A lack of long-term policy commitments and regulatory uncertainty can deter investors from supporting CCUS projects. Stable and predictable policies are crucial for fostering a conducive investment environment.

- Economic Viability: Demonstrating the economic viability of CCUS projects is essential for attracting private sector investments. This involves addressing upfront costs and ensuring ongoing operational costs are competitive.

- Land Use and Permitting: Securing permits for land use, especially for underground storage of captured carbon, can be a complex and time-consuming process. Legal and regulatory hurdles in obtaining necessary licenses can delay project timelines.

- Scale and Scope: Achieving the necessary scale for a significant impact on emissions reduction can be challenging. Determining the optimal scope and scale of CCUS projects requires careful consideration of regional characteristics and industrial profiles.

Several CCUS projects are currently underway in India, such as:

- The ONGC Hazira CCUS project will capture CO2 from the Hazira gas processing plant and inject it into a deep saline aquifer under the seabed.

- The NTPC Sipat CCUS project: This project will capture CO2 from the flue gas of the Sipat power plant and use it to produce urea, a fertiliser.

- The Reliance Industries Jamnagar CCUS project will capture CO2 from the Jamnagar refinery and use it to produce petrochemical feedstock ethylene.

These projects are expected to help India gain valuable experience in deploying CCUS technologies.

Way forward to promote the deployment of CCUS in India

The Govt of India shall encourage the deployment of CCUS in India by:

- Developing a comprehensive regulatory and policy framework for CCUS. This framework shall provide clear guidelines for permitting, operating, and monitoring CCUS projects.

- Investing in the development of CCUS technical expertise. This can be done by supporting research and development on CCUS technologies and training CCUS professionals.

- Raising public awareness of CCUS and its benefits. This can be done through public education campaigns and by engaging with stakeholders such as environmental groups and community leaders.

- Providing financial incentives for CCUS projects. Tax breaks, grants, and other financial assistance can do this. By taking these measures, India can accelerate the deployment of CCUS technology and achieve its climate commitments.

Role of an Engineering Consultant

Engineering consultants play a crucial role in developing and implementing critical opportunities for carbon capture and storage (CCS), as indicated below.

- Project Design and Feasibility Studies: Engineering consultants can contribute to the initial stages of CCS projects by conducting feasibility studies, assessing project viability, and designing efficient capture and storage systems.

- Technology Selection and Integration: There’s an opportunity for consultants to evaluate various carbon capture technologies and integrate them seamlessly into existing industrial processes or power plants.

- Regulatory Compliance: Navigating complex regulatory landscapes is a significant challenge for CCS projects. Engineering consultants can help clients understand and comply with environmental regulations and permit requirements.

- Risk Assessment and Mitigation: Consultants can identify and assess potential risks associated with CCS projects, offering strategies to mitigate these risks and ensure the safe and effective implementation of the technology.

- Site Selection and Characterization: Identifying suitable storage sites for captured carbon dioxide is critical. Engineering consultants can contribute to site selection and characterisation studies considering geological, environmental, and safety factors.

- Economic and Financial Analysis: Consultants can conduct economic and financial analyses to help clients understand CCS projects’ costs and potential returns. This includes evaluating funding options, incentives, and financial risks.

- Public Engagement and Stakeholder Management: Public acceptance is crucial for the success of CCS projects. Engineering consultancy firms can assist in developing communication strategies, engaging with local communities, and managing stakeholder expectations.

Conclusion

CCUS is a promising technology that can help India reduce greenhouse gas emissions, improve energy security, and create new jobs and industries. The Government of India supports CCUS development, and several CCUS projects are currently underway in the country. However, there are several challenges to deploying CCUS in India, including cost, lack of infrastructure, and public acceptance. India has the potential to overcome these challenges and become a leader in deploying CCUS technology. As a signatory to international climate agreements like the Paris Agreement, India can demonstrate its commitment to sustainable development by integrating CCUS into its overall climate strategy and contributing to global climate goals.

[1] CCUS Report_Part I Web Only (niti.gov.in)

[2] Pathways & Industrial Approaches for Utilization of CO2 – Tech Speak – Tata Consulting Engineers’ Blog (tce.co.in)