At Tata Consulting Engineers Ltd (TCE), we established our Mining & Metallurgy business unit in 2005 to meet the evolving needs of the ferrous and non-ferrous metals industry. Today, we provide end-to-end solutions across the entire value chain, covering mineral exploration, beneficiation, resource management, and metal manufacturing and processing.

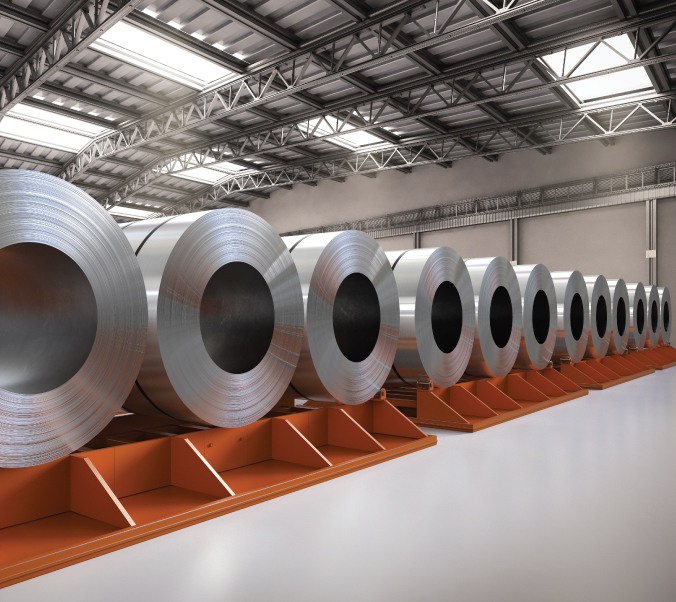

With deep expertise in metallurgy, we offer advanced solutions in mineral beneficiation, process optimisation, de-bottlenecking, material handling, and infrastructure development. We support industries in iron and steel as well as non-ferrous sectors such as alumina, aluminium, lead zinc, and copper. We also work with emerging metals, delivering seamless services from raw material management to utilities, setting up greenfield plants, and modernising brownfield facilities with recycling solutions to support a circular economy.

Over the years, we have successfully delivered more than 500 projects, including 150 international assignments. We introduced India’s first 3D Engineering Platform for executing integrated steel plants and have consistently demonstrated engineering excellence in MSA projects across the Middle East, Europe including Scandinavia, and Australia. Our highly efficient Onsite Offsite Engineering Model ensures seamless project execution while balancing operational demands and long-term business goals.

We have contributed to some of the world’s largest metallurgy projects, including a 10 million tonnes per annum steel plant and ore handling facilities exceeding 100 million tonnes per annum. We have also pioneered decarbonisation roadmaps for steel plants globally, advanced structural steel engineering and fabrication, and played a key role in driving green steel solutions.

Key Projects

With a strong track record of delivering world-class projects, we take pride in shaping some of the industry’s most complex and large-scale developments.

- The world’s largest single-stream copper smelter in India

- The world’s largest single-stream zinc concentrator in South Africa

- The world’s second-largest alumina refinery

- The largest copper smelter in the ASEAN and Oceania region

- The largest aluminium scrap recycling facility in the Middle East

- India’s first Grain Oriented Electric Steel GOES Plant

- The largest brownfield steel plant expansion in the UAE

- India’s first E Scrap and copper scrap recycling facility

As leaders in low carbon steel production, we integrate sustainable technologies such as hydrogen based steelmaking, carbon capture, and energy efficient processes to help industries transition towards greener and more sustainable manufacturing.

We provide end-to-end solutions for the ferrous metals industry, covering raw material handling, ironmaking, and the entire steel value chain. This includes all process routes, both new and conventional, along with rolling and finishing mills. Our expertise spans blast furnaces, direct reduced iron (DRI) processes including DRI-EAF, DRI-REF, and hydrogen-based DRI, as well as sinter and pellet plants, die making, coke ovens and by-product plants, and lime calcining. We deliver advanced engineering for steelmaking and ferroalloy plants, special steels such as electric steel, advanced defence-grade steel, and stainless steel. Our expertise also extends to rolling mills for flat and long products, as well as coating and finishing processes.

Our non-ferrous capabilities cover raw material handling, refining, smelting, recycling, processing, rolling, and fabrication, providing a comprehensive approach to sustainable and efficient non-ferrous metal production. We offer end-to-end solutions that ensure smooth material flow, advanced refining techniques, precision in metal forming and fabrication, and sustainable recycling practices. Our focus is on improving efficiency while maintaining environmental responsibility in metal production. Our expertise includes optimising zinc processing operations, enhancing productivity, and implementing sustainable practices across the non-ferrous metals industry.

We provide comprehensive technical support for mineral beneficiation, covering sampling and lab analysis, simulation, scale-up, flow sheet development, and the implementation of the Global Industry Standard on Tailings Management (GISTM) to promote sustainable and responsible practices. Our expertise ensures accurate mass and water balance, along with process control engineering, P&ID development, equipment sizing and selection, and layout engineering. We also conduct CAPEX and OPEX assessments, process audits, and performance optimisation studies to enhance efficiency and sustainability.

Engineering the Path to Decarbonisation for a Lead...

A leading steel manufacturer in the United Kingdom sought to transition from a conventional, carbon- ...

Read More

The world’s largest and developed zinc deposit site was discovered over 30 years ago but remained unexcavated due to its viability.

Learn More

© Tata Consulting Engineers Limited. All Rights Reserved | Site Credits:DV