Technovation

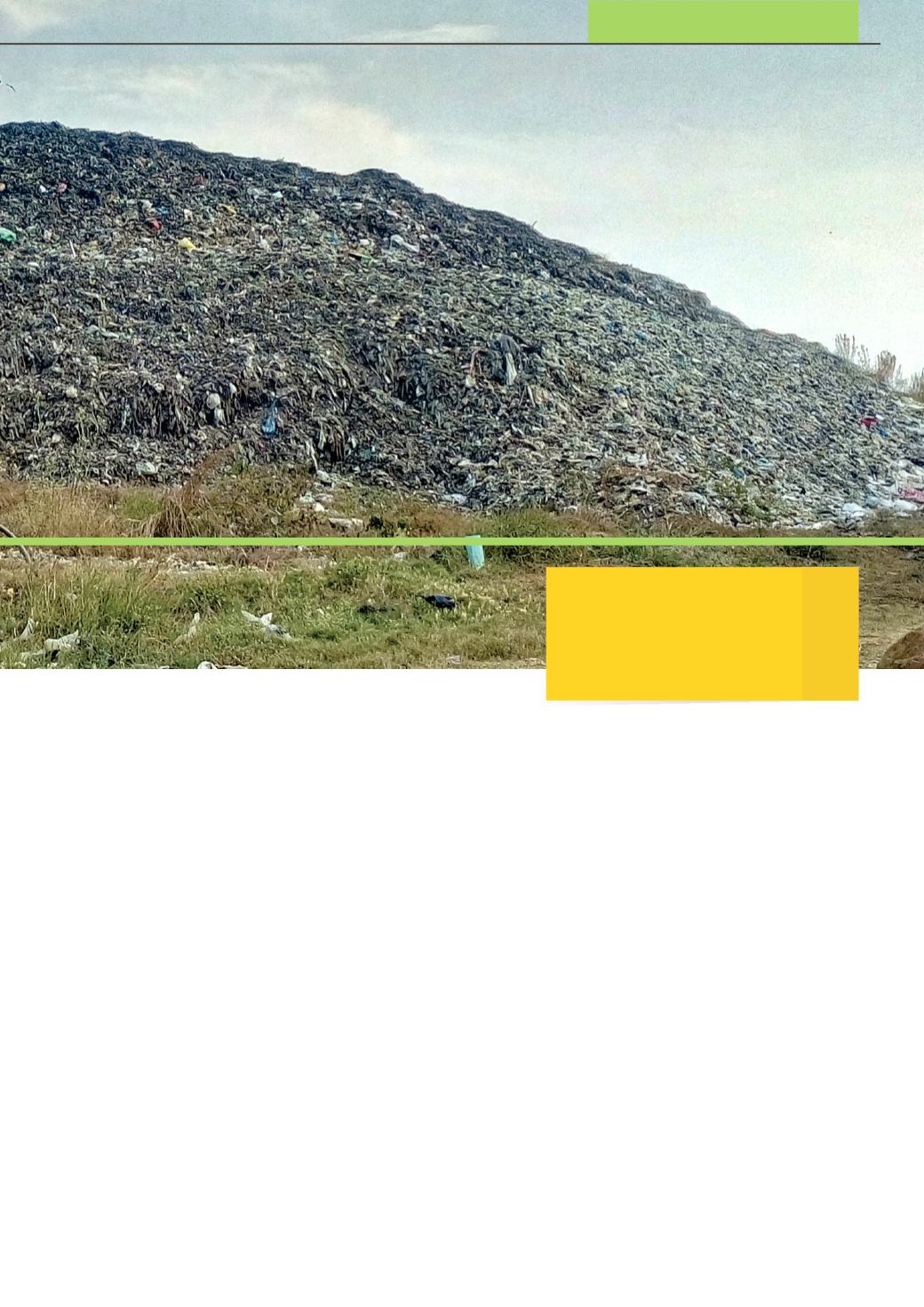

Urban waste

worldwide is expected

to touch 2.2 billion

tonnes per year.

The science of WTE

Several technology solutions are available but the

right technology that will work best starts right

from the source – TRASH! MSW is the trash from

households, shops and establishments, commercial

outlets etc. The composition and characteristics

(moisture content and calorific value) determines the

WTE technology or any waste treatment process.

Waste can be organic (food waste, etc.) and waste

that can be burned(paper, plastic, leather, textile,

etc.); waste that cannot be burned such as inerts,

glass, metals, etc. Based on these parameters, a

combination of technologies can be adopted for WTE.

WTE –Waste to Energy

Waste to energy is the technology-based processing

of waste for generating energy in the form of

electricity/heat/bio-fuel. The full suite of WTE

technologies include thermal processes like mass

burn incineration and gasification & non-thermal

processes like anaerobic digestion and landfill-gas

recovery. The technologies used for WTE are:

• Thermal Technologies –

Direct Combustion (Mass

Burn and RDF-MSW-segregated or otherwise is

burned and the heat generated is used to produce)

steam or electricity.

• Pyrolysis –

This is a form of gasification that occurs

at relatively low temperatures of 300-600 degrees

centigrade in the absence of oxygen.

• Conventional Gasification –

This is a process that

converts any material containing carbon such as

coal, biomass or MSW into syngas. In the controlled

presence of oxygen, temperatures of 480-1650

degrees centigrade break the feedstock molecules

apart and recombine them into syngas.

• Plasma Arc Gasification –

This method uses a

plasma torch to provide supplemental heat for the

gasification process wherein temperatures can

reach 2760 - 11,000 degress centigrade.

15