Pressure Relief Valve – ASME Section VIII Unfired Pressure Vessel Code Requirements

Pressure Safety Valves (PSV) are designed and manufactured using American Petroleum Institute (API) and American Society of Mechanical Engineers (ASME) standards. There always needs to be clarity about whether only API or ASME standards can be used for sizing PSV, as they are different but complementary standards. When both standards are properly applied for the design of PSVs, complete safety and success of the project can be achieved. Another way of looking at these two standards is discussed in this article.

The ASME section VIII-div. 1, section U-1 gives vessel classification outside the jurisdiction of the code. The vessels which fall under this area are:

- Those under federal control

- Those having internal or external operating pressure less than 15 psig.

- Those having an outside diameter of six inches or less.

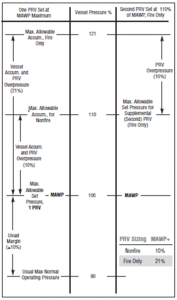

Figure 1: One PRV for non-fire and fire case

Overpressure Protection

Overpressure is the pressure increase over the set pressure of the relieving device. Overpressure is expressed in pressure units or as a percentage of set pressure. Overpressure is the same as accumulation only when the relieving device is set to open at the maximum allowable working pressure of the vessel.

As per ASME section VIII-div.1, UG-125(c), for all pressure vessels other than unfired steam boilers should be protected by PSV to prevent pressure from rising more than 10% or 3 psi (whichever is greater) above maximum allowable working pressure (MAWP), except for cases 1 & 2 as mentioned below. (See Figure 1)

From this clause, it is obvious that when the MAWP of a vessel is more than 30 psi, one should specify overpressure as 10% and till the MAWP of 30 psi, overpressure shall be specified as 3 psi.

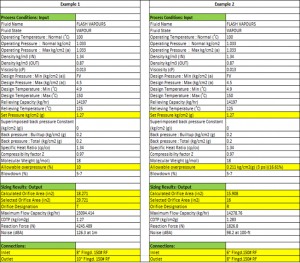

To illustrate the difference in sizing results of the relieving device, please refer to two examples of the same instrument tag. In example 1, the overpressure is set at 10%; in example 2, the overpressure is set at 3 psi (20 kPa / 0.211 kg/cm2).

Example 1: Overpressure set at 10% Example 2: Overpressure set as 3 psi (0.211kg/cm2)

In the above examples, the set pressure of the relieving device is 1.27 kg/cm2; overpressure selection at 10 % of set pressure would result in overpressure being 0.127 kg/cm2, which stands at < 3 psi (0.211 kg/cm2). In such cases, as per ASME section VIII, UG-125(C), overpressure should be selected as 3 psi (0.211 kg/cm2) instead, as shown in Example 2 above, which demonstrates that with such an overpressure selection, the PSV orifice area/designation stands lower than Example 1 by a significant margin. An oversized PSV in Example 1 would also result in cost implications.

Case 1: UG 125 (c) 1- when multiple PSVs are provided and set per UG 134(a), they shall prevent the pressure from rising more than 16% or 4 psi, whichever is greater than MAWP.

Case 2: When the pressure vessel is exposed to fire or other unexpected sources of external heat, the PSV shall be capable of preventing the pressure from rising more than 21% above MAWP

As per ASME Section VIII, UG-134(a), If a single PSV is used, it must be set at a pressure not higher than MAWP. When more than one PSV is used to meet the relieving capacity requirement, only one valve can be set at a pressure lower than or equal to MAWP. All additional PSVs can be set at higher pressure but, in any case, not more than 105% of MAWP. (See Figure 2)

As per ASME Section VIII, UG-134(b), protective devices permitted by UG 125 (c)(2) (Such as fire case) can be adjusted to operate at a pressure not greater than 110% of MAWP. However, if such a device is used to meet the requirement of both UG125(c) and UG125(c)(2), it should be set at a pressure at most MAWP.

Figure 2: Two or more PRV used for non-fire case but also sized for fire case

Reference :

1) ASME Section VIII

2) Anderson Greenwood technical