Page 24 - Tcexpression2021 - Sept to Dec 2020

P. 24

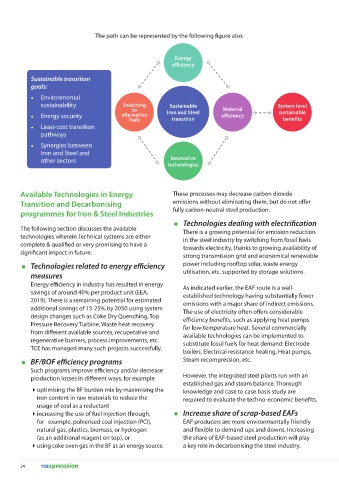

The path can be represented by the following figure also:

Energy

efficiency

Sustainable transition

goals:

• Environmental

sustainability Switching Sustainable System level

to Iron and Steel Material sustainable

• Energy security alternative efficiency

fuels transition benefits

• Least-cost transition

pathways

• Synergies between

Iron and Steel and

other sectors Innovative

technologies

Available Technologies in Energy These processes may decrease carbon dioxide

Transition and Decarbonising emissions without eliminating them, but do not offer

programmes for Iron & Steel Industries fully carbon-neutral steel production.

Technologies dealing with electrification

The following section discusses the available There is a growing potential for emission reduction

technologies wherein Technical systems are either in the steel industry by switching from fossil fuels

complete & qualified or very promising to have a towards electricity, thanks to growing availability of

significant impact in future:

strong transmission grid and economical renewable

Technologies related to energy efficiency power including rooftop solar, waste energy

measures utilisation, etc. supported by storage solutions.

Energy efficiency in industry has resulted in energy As indicated earlier, the EAF route is a well-

savings of around 40% per product unit (EEA, established technology having substantially fewer

2019). There is a remaining potential for estimated emissions with a major share of indirect emissions.

additional savings of 15-25% by 2050 using system The use of electricity often offers considerable

design changes such as Coke Dry Quenching, Top efficiency benefits, such as applying heat pumps

Pressure Recovery Turbine, Waste heat recovery for low-temperature heat. Several commercially

from different available sources, recuperative and available technologies can be implemented to

regenerative burners, process improvements, etc. substitute fossil fuels for heat demand: Electrode

TCE has managed many such projects successfully.

boilers, Electrical resistance heating, Heat pumps,

BF/BOF efficiency programs Steam recompression, etc.

Such programs improve efficiency and/or decrease

production losses in different ways, for example However, the integrated steel plants run with an

established gas and steam balance. Thorough

optimising the BF burden mix by maximising the knowledge and case to case basis study are

iron content in raw materials to reduce the required to evaluate the techno-economic benefits.

usage of coal as a reductant

increasing the use of fuel injection through, Increase share of scrap-based EAFs

for example, pulverised coal injection (PCI), EAF producers are more environmentally friendly

natural gas, plastics, biomass, or hydrogen and flexible to demand ups and downs. Increasing

(as an additional reagent on top), or the share of EAF-based steel production will play

using coke oven gas in the BF as an energy source. a key role in decarbonising the steel industry.

24 TCExpresssion