Page 8 - TATA Consulting Engineers Limited | PMC

P. 8

8

Project Management Consultancy

Case Study

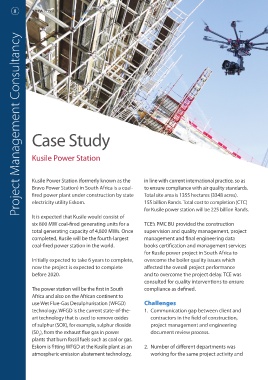

Kusile Power Station

Kusile Power Station (formerly known as the in line with current international practice, so as

Bravo Power Station) in South Africa is a coal- to ensure compliance with air quality standards.

fired power plant under construction by state Total site area is 1355 hectares (3348 acres).

electricity utility Eskom. 155 billion Rands. Total cost to completion (CTC)

for Kusile power station will be 225 billion Rands.

It is expected that Kusile would consist of

six 800 MW coal-fired generating units for a TCE’s PMC BU provided the construction

total generating capacity of 4,800 MWs. Once supervision and quality management, project

completed, Kusile will be the fourth-largest management and final engineering data

coal-fired power station in the world. books certification and management services

for Kusile power project in South Africa to

Initially expected to take 6 years to complete, overcome the boiler quality issues which

now the project is expected to complete affected the overall project performance

before 2020. and to overcome the project delay. TCE was

consulted for quality interventions to ensure

The power station will be the first in South compliance as defined.

Africa and also on the African continent to

use Wet Flue-Gas Desulphurisation (WFGD) Challenges

technology. WFGD is the current state-of-the- 1. Communication gap between client and

art technology that is used to remove oxides contractors in the field of construction,

of sulphur (SOX), for example, sulphur dioxide project management and engineering

(S0 ), from the exhaust flue gas in power document review process.

2

plants that burn fossil fuels such as coal or gas.

Eskom is fitting WFGD at the Kusile plant as an 2. Number of different departments was

atmospheric emission abatement technology, working for the same project activity and

TCE_Bro2017_PMC Final (2nd Feb).indd 8 2/5/18 2:09 PM