March 2024

The aviation industry is projected to grow substantially, with an estimated 4 to 5% increase in air traffic annually. Some regions may experience higher growth rates, leading to more than 3 billion passengers travelling worldwide yearly.

Learn MoreAUTHORS

S Sakthivel

Deputy General Manager

Amit Sharma

MD & CEO

Atul Choudhari

Chief Technology Officer (CTO)

Nov 2023

Natural Gas (NG) is a versatile and efficient source of energy. It is commonly used fuel for heating applications in residential, commercial, and industrial sectors. It is also used as a fuel for electricity generation in power plants. Natural gas provides a reliable and continuous source of en ...

Learn MoreAUTHORS

S Sakthivel

Deputy General Manager

Amit Sharma

MD & CEO

Atul Choudhari

Chief Technology Officer (CTO)

Oct 2023

Various devices and technologies for energy storage have been developed to address the intermittent nature of renewable energy sources and ensure a stable and reliable energy supply. These storage solutions play a crucial role in efficiently utilising clean energy.

Learn MoreAUTHORS

S Sakthivel

Deputy General Manager

Shireesh S Swami

Associate Vice President

Amit Sharma

MD & CEO

Atul Choudhari

Chief Technology Officer (CTO)

Arnab Dandapath

Senior Manager

Feb 2023

Energy usage in industrial, domestic and transportation accounts for 73.2% of the total1 greenhouse gas (GHG) emissions (Refer Figure 1). The use of fossil fuels is reducing in developed economies primarily due to the increase in the cost of fossil fuel(s), its fluctuations, depletion of resour ...

Learn MoreAUTHORS

Mr Amit Sharma

MD & CEO

Mr Atul Choudhari

Chief Technology Officer

Mr S Sakthivel

Assistant General Manager

July 2022

Currently, the iron and steel industries face many challenges to achieve multiple objectives simultaneously. The objectives include: - Maintaining high product quality - Boosting productivity - Reducing costs - Reducing energy consumption - Mitigating environmental emissions. In this whitepaper ...

Learn MoreAUTHORS

Mr Amit Sharma

MD & CEO

Mr Atul Choudhari

Chief Technology Officer

Mr Shireesh.S. Swami

Senior General Manager

Mr S Sakthivel

Assistant General Manager

March 2022

The steel industry emits various pollutants like particulates, obnoxious gases, and harmful liquids, but this paper shall deal only with Particulate Matter (PM) emissions. In this paper, the significant areas of an integrated steel plant have been identified as the source of particulate emissio ...

Learn MoreAUTHORS

Mr Bibhas Kumar Dey

General Manager

March 2022

Considering the variability of renewable energy generation from principal sources like wind and solar, energy supply reliability would heavily depend on ESS to store surplus energy for later use when demand exceeds the generation. Thus, ESS would be a significant enabler for an energy transitio ...

Learn MoreAUTHORS

Mr Amit Sharma

MD & CEO

Ms D Geethalakshmi

General Manager

Mr Kiran Nandanan

Engineer Trainee

Mr Aniket Nitin Kekane

Engineer Trainee

Sept 2021

Widespread concerns due to the COVID-19 pandemic led to the closure of many industrial facilities. Several projects and construction activities were also suddenly stopped. It was impossible to devise one single approach and continue with business as usual in that environment. All industry segme ...

Learn MoreAUTHORS

Mr Amit Sharma

MD & CEO

Mr Atul Choudhari

Chief Technology Officer

July 2021

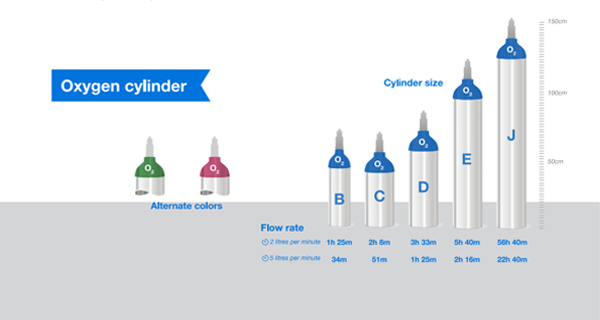

India is almost at the end of the devastating second wave of COVID-19, which had spread across the country and claimed thousands of lives, and affected millions. The country’s medical infrastructure proved insufficient as many patients needed oxygen support and hospital beds for survival. The ...

Learn MoreAUTHORS

Mr Amit Sharma

MD & CEO

Mr Atul Choudhari

Sr. General Manager

Mr Shireesh.S.Swami

Sr. General Manager

June 2021

This paper provides the technical concept and feasibility of using LPG Cylinders for medical oxygen usage. Implementation of the concept provided in this paper shall involve further Statutory, Legal and other approvals. They must be done with the proper involvement of Government authorities. Ad ...

Learn MoreAUTHORS

Mr Amit Sharma

MD & CEO

Mr Atul Choudhari

Sr. General Manager

Mr Shireesh S Swami

Sr. General Manager

February 2021

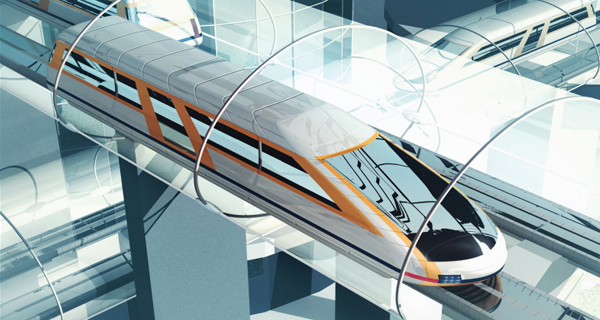

There are four modes of transport in the world - Road, Rail, Water and Air. #Hyperloop is the fifth mode of transport faster than air and eco-friendly compared to the other transport systems. The concept of the Hyperloop was put forth by Tesla and Space X founder Elon Musk in 2012. Hyperloop is ...

Learn MoreAUTHORS

Mr.Sanjoy Chowdhury

Senior General Manager

June 2021

Satisfying energy demands forms an integral part of the development of the world. Growing concerns over climate change, especially finding an alternate means of energy sources to the present fossil fuels, has increased hydrogen interest. Hydrogen is a flexible and alternative energy carrier wit ...

Learn MoreAUTHORS

Mr Amit Sharma

MD & CEO

Mr Atul Choudhari

Deputy Chief Technology Officer

June 2021

Various new technologies have been developed and existing technologies modified to achieve sterilization and decontamination of items that are used in daily life and to control the spread of such contactable disease-causing micro-organisms

Learn MoreAUTHORS

Mr Shireesh.S.Swami

Senior General Manager

June 2021

A boiler explosion is a catastrophic failure. It carries dirt, debris, and higher-temperature gases in all directions at high speeds. It causes severe damage to everything in the vicinity. The explosive potential is always present, primarily if regular maintenance and repair are not performed. ...

Learn MoreAUTHORS

Mr Lakshmana Rao

Sr. General Manager

April 2021

As the country is dealing with the second wave of the pandemic, the need for oxygen is critical and its availability a crisis. This paper presents an out of the box solution of converting CO2 fire extinguishers and LPG cylinders for medical oxygen use. It also suggests the conversion of industr ...

Learn MoreAUTHORS

Mr Amit Sharma

MD & CEO

Mr Atul Choudhari

Chief Technology Officer

March 2021

Coke oven batteries play a pivotal role in an integrated steel plant for uninterrupted supply of metallurgical coke to Blast Furnace and coke oven gas to the other user apart from its consumption. During the operational life cycle, they are subjected to continuous thermal, mechanical, static, a ...

Learn MoreAUTHORS

Mr Bulu Chandra

Deputy General Manager

Mr Manos De

Senior General Manager

Mr Balagouda Pati

General Manager

Mr Sphatick Bhattacharyya

Consultant

February 2021

Coal is primarily used as fuel in power generation. However, coal can also be used as an alternate source for making liquid fuels. Recent advancements in technology have successfully demonstrated the conversion of coal into liquid fuels and many other useful chemicals. CTL (Coal to liquid) tech ...

Learn MoreAUTHORS

Mr Atul Choudhari

Deputy Chief Technology Officer

February 2021

Irrespective of the reasons for relocating a manufacturing/production facility, every plant relocation comes with its own set of challenges. Detailed planning in the initial phase of relocation and communication to all the stakeholders involved in execution will help minimize the challenges and ...

Learn MoreAUTHORS

Mr Shireesh .S. Swami

Senior General Manager

Mr Atul Choudhari

Senior General Manager

July 2020

The imposition of strict lockdown to counter the spread of the highly contagious COVID-19 virus brought the country to a sudden and grinding halt. Little was envisaged at that time of the plight that would befall the silent workforce that was engaged in building our nation. In this document, as ...

Learn MoreAUTHORS

Mr Manos De

Discipline Head

May 2020

Nigeria is the gas giant of Africa and certainly a leading crude oil producer in the World. With an estimated gas reserve of about 200 tscf (rank#1 in Africa) and production of slightly more than 8 bscf/day, its the largest gas producer in Africa. However, the gas-based economy in Nigeria is ye ...

Learn MoreAUTHORS

Mr Ajay Pratap Singh

Head Business Development - Africa

May 2020

During the first week of May 2020, after the partial lifting of the lockdown, two major accidents occurred while restarting the two process plants – a polymer plant and, a paper plant. These accidents highlight the importance of safe restarting procedures after the plants have been shut down ...

Learn MoreAUTHORS

Mr Shireesh Swami

Technology Principal

May 2020

This article is a viewpoint that looks at what happens to the strategic goals and action plans in the current highly uncertain COVID19 scenario. An attempt has been made to try and estimate the business impact and possible precautionary measures to stay afloat and still focus on meeting the set ...

Learn MoreAUTHORS

Mr Gangadhara Siddaiah

Head of Sales – Power

Dr Rajashekhar Malur

Chief Technology Officer

May 2020

The construction industry requires the physical presence of a workforce at the site for myriad activities, involving both skilled and unskilled workers, working in proximity to each other, in concentrated groups. The construction work itself happens in a relay fashion with strong interdependenc ...

Learn MoreAUTHORS

Mr Manos De

Discipline Head

Dr Rajashekhar Malur

Chief Technology Officer

May 2020

Forecasts have a notoriety of being unreliable even under normal conditions, and look all the more dubious in current times, as there are simply too many unknowable aspects.

Learn MoreAUTHORS

Mr Rajeev Tanna

Chief Risk Officer

October 2019

The global automotive industry is on the verge of disruption. The transport sector is the highest consumer of oil and the second-highest contributor to CO2 emissions worldwide. Rapid developments in electric mobility will transform the automotive industry by addressing the growing concerns of t ...

Learn MoreAUTHORS

Mr Amit Sharma

MD & CEO

Dr Rajashekhar Malur

Chief Technology Officer

Global climate change and the technologies to minimize greenhouse gas emissions are at the center of discussion in every global environmental forum. Carbon capture technology is one of such techniques which can be implemented to reduce atmospheric emissions of carbon dioxide from industrial ins ...

Learn MoreAUTHORS

Mr.Atul Choudhari

Senior General Manager

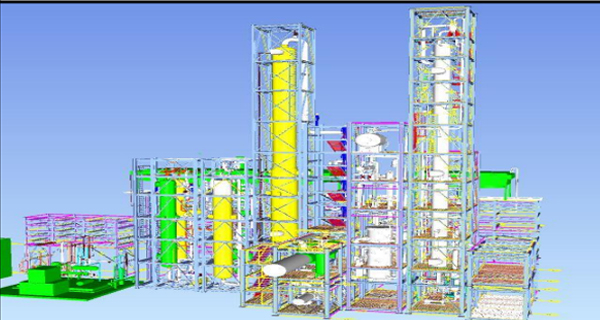

The economic scenario of the world is changing rapidly. Due to the volatility in oil and natural gas prices, there is still uncertainty in the supply, demand, and pricing of chemicals. Considering advancements in technology, new investments are happening in remote areas which are close to eithe ...

Learn MoreAUTHORS

Mr.Atul Choudhari

Senior General Manager

Consistent technology maturity over centuries in the industrial automation domain firing off from field instrumentation to control system(s) enables more plant productivity, more automation enabling stress-free life for plant operators, remote monitoring and operation of plants including but no ...

Learn More

Economic scenario of the world is changing rapidly. Due to the volatility in oil and natural gas prices, there is still uncertainty in supply, demand and pricing of chemicals. Considering advancements in technology, new investments are happening in remote areas which are close to either raw mat ...

Learn More

Continuous Annealing and Processing Line (CAPL) produces value-added high quality advanced high strength CRCA (cold rolled close annealed) steel of varying thickness in the range of 0.4 mm to 2.3 mm which is mostly used in the automobile manufacturing industries. One of our customers intended t ...

Learn MoreAUTHORS

Mr.Anupam Roy

Mr.Biswarup Pal

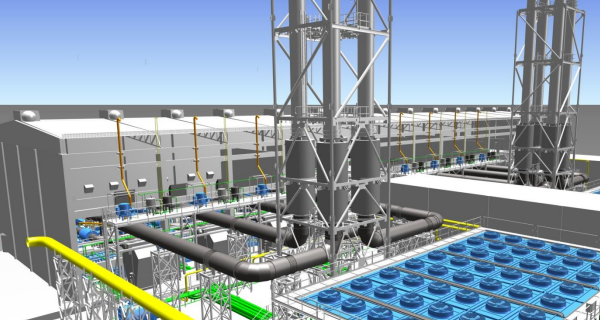

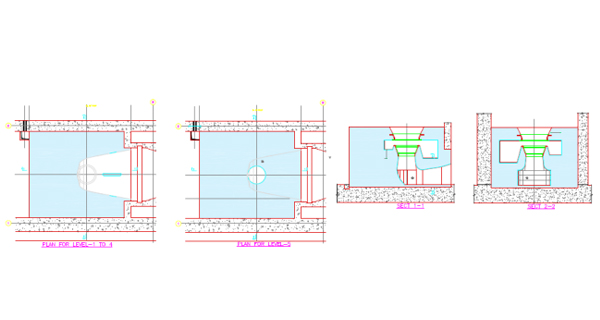

Power plants and chemical and industrial plants have very large requirements of raw water for their process needs. Water which is very scarce these days is got from a source nearest to the plant; which can be a river, lake, or a dam reservoir, and this water is then pumped and stored within pla ...

Learn MoreAUTHORS

Mr.Surovi Ganguly

Mr.Rajaraman Ramanathan

Coal fired thermal power plants generally require a huge quantity of cooling water for the operation of plants. Water requirement increases with a number of units and unit capacity. For coastal power plants, seawater is a normal source of such cooling water. In one of the executed power plant c ...

Learn More

Stacker reclaimer is the equipment for raw material handling & management in Steel, Power, Cement, and many other Plants. The stockpile of material is built to augment feeding when the regular supply of the same is suspended. Stacker Reclaimer is mounted on wheels that travel on rails over a lo ...

Learn MoreAUTHORS

Ms.Sohini Mishra

Manager

Mr.Sanjoy Chowdhury

Sr. General Manager

This paper is to enable a better understanding of the sewage network systems & it’s management in India. The reasonable gaps/challenges at a broad level in this sector are identified and addressed with proper techno-economic approach and design criteria to enable this sector to develop on a s ...

Learn MoreAUTHORS

N.Purnachandra Rao

Dr. S.Sakthivel

The sustainment of all living things is due to a combination of gases in defined proportions that collectively form the atmosphere. Any increase or decrease in the percentage of these gases will cause imbalance and can be harmful to survival. The emission of gases that contain Sulphur oxides (S ...

Learn MoreAUTHORS

Mr.Sunil.P. Agarwal

Steam & water analysis system (SWAS) is dedicated to the analysis of steam & water in power plants to ensure the protection of the boiler and turbine from impurities; by preventing corrosion/salt deposition in boiler tubes and corrosion, salt/silica deposition, erosion in turbines blades. The m ...

Learn More

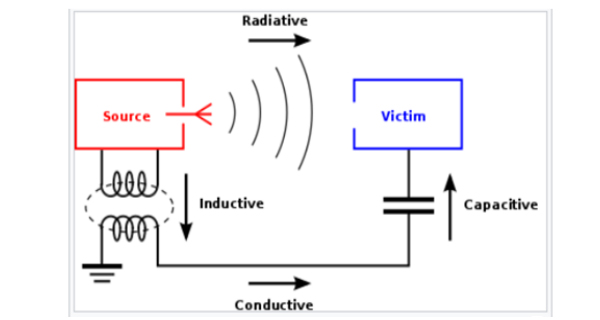

Electromagnetic Compatibility (EMC) is used to describe how well a device can function in its EM environment without causing any unwanted effects on the surrounding equipment. Electromagnetic Interference (EMI) is a result of electric or magnetic fields acting on the device causing it to malfun ...

Learn MoreAUTHORS

Mr.C Sailaja

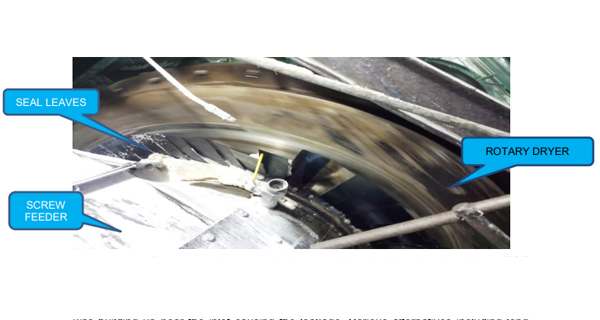

In one of the soda ash production facilities, there was a significant quantity of product loss in the drying process. The product was spilling from the inlet flanges of the rotary dryers. The target was to minimize the loss of product so as to enhance production by minimizing the downtime of th ...

Learn MoreAUTHORS

Mr.Shireesh Swami

Greenhouse gases are generated by various industrial processes. Though power generation is a known major contributor of greenhouse gas (GHG) emissions, a considerable amount of greenhouse gases are released from other energy intensive industries as well. Petroleum refining is one such energy in ...

Learn MoreAUTHORS

Mr.Atul Choudhari

A pipeline is the fastest and most reliable means of fluid transportation compared to other transportation modes like rail or road tankers. However, leakage is the main threat to pipeline transfer. The pipelines often carry hazardous materials and may pass through areas of the human population. ...

Learn MoreAUTHORS

Mr.Atul Choudhari

Coal is primarily used as fuel in power generation. However, coal can also be used as an alternate source for making liquid fuels. Recent advancements in technology have successfully demonstrated the conversion of coal into liquid fuels and into many other useful chemicals. CTL (Coal to liquid) ...

Learn MoreAUTHORS

Mr.Atul Choudhari

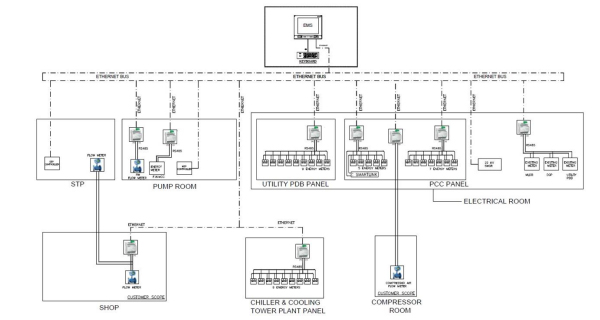

Utilities such as air, water, gas, electricity etc. are required for the process and manufacturing industry. The quantity of such utilities needs to be monitored in a precise way to ensure efficient usage. This can be monitored through Energy Management System (EMS) and controlled effectively t ...

Learn MoreAUTHORS

Mr.Abhijeet Vaidya

Mr.Vijay Barv

TCE provides services as a Design engineering Consultant/ Owner’s engineer/ Project Management consultant for many industrial projects wherein the buildings are generally PEB. TCE plays a crucial role in the conceptualization and framing of the specifications of the PEB structures so that cli ...

Learn MoreAUTHORS

Mr.Amol Banpatte

Mr.Uday Mahadik

Mr.Vijay Barve

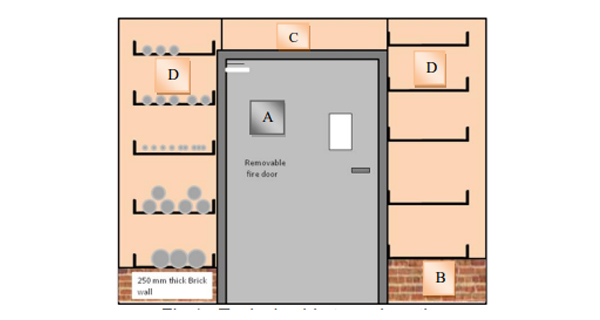

Cable tunnels are mainly used for the distribution of bulk power across large scale plants, substations, and smart cities. Cables are routed through cable trays installed in tier formation on either side of the cable tunnels. Fire hazard is one of the major concerns in underground cable tunnels ...

Learn MoreAUTHORS

Mr.Anupam Roy

Process simulation is a useful and powerful tool to model chemical process flowsheets of varying complexity. Modern day simulators are built with comprehensive pure component databanks, an exhaustive library of thermodynamic systems and physical property estimation methods, initial estimate gen ...

Learn MoreAUTHORS

Mr.Atul Choudhari

Emission regulations have become more stringent with the latest Notification issued by Ministry of Environment and Forest in Dec.’2015. Many operating power plants need to revamp their flue gas pollution control devices to meet the prescribed environmental norms. The most commonly used pollut ...

Learn MoreAUTHORS

Mr.R Somasundaram

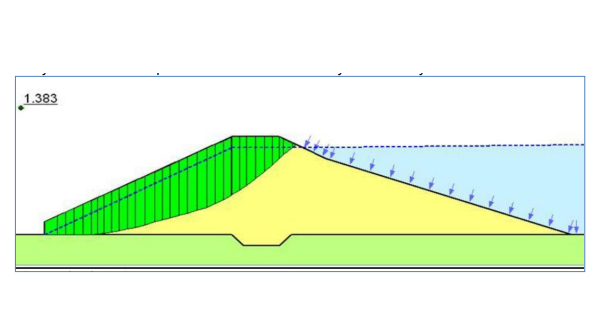

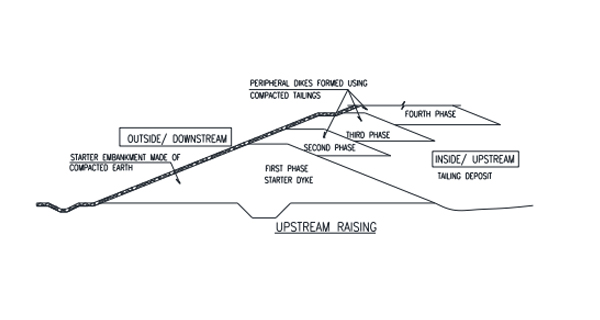

Beneficiation plant in the Iron mines separates contaminants & fines called tailings from the ore. These tailings in a slurry form are generally disposed of in a vast area of land encompassed by an embankment called as tailing pond. Under the present socio-political scenario with limited availa ...

Learn MoreAUTHORS

Mr.Sanjoy Chowdhury

Sr. General Manager

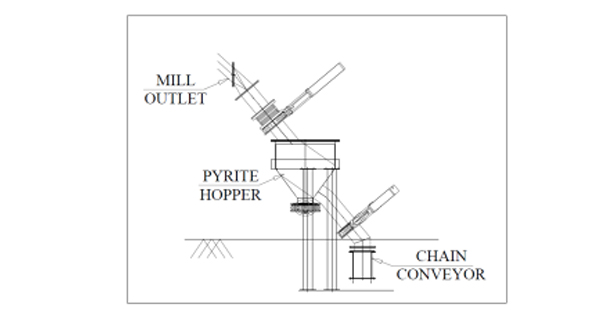

In thermal power plants, Mill Reject Handling System (MRHS) is provided to evacuate mill rejects (Pyrites) from the pyrite hopper and convey it to the mill reject silo. The conventional methods of MRH systems include Pneumatic type, Mechanical type (By Belt / Chain conveyors) and Hydraulic type ...

Learn MoreAUTHORS

Mr.Siddharth Rane

Mr.H Ramakrishna

Protection and strengthening of rock surfaces within optimum time, cost and with adequate reliability is among the challenges on the projects. This article shares TCE’s experience in protecting and strengthening of rock surfaces in deep excavation, valley and hilly terrain.

Learn MoreAUTHORS

Mr.Sanjeev Gupta

General Manager

Mr.S Saranya

Assistant Manager

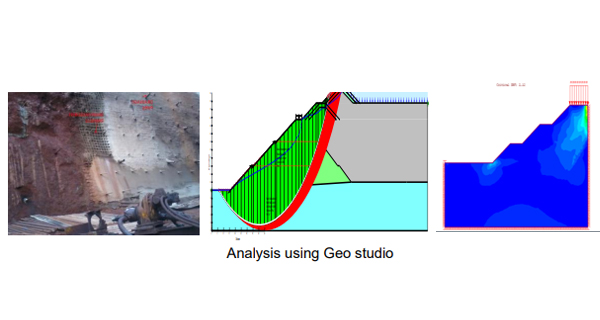

Slope stability analysis in soil strata helps in optimizing slope for cost and time-effective construction. This article describes the procedure of carrying out slope stability analysis by using Geo-studio and Phase 2 software. Slope stability analysis has numerous applications in various const ...

Learn MoreAUTHORS

Mr.Sanjeev Gupta

General Manager

Mr.S Saranya

Assistant Manager

Coal fired utility power generation plants are primarily designed as base load units in India. In order to meet the load demand of future industrial growth large capacity power plants with super / ultrasuper critical technology are envisaged which offers higher efficiencies with lower emissions ...

Learn MoreAUTHORS

Sarath Chandra Allu

Combined heat and power plant which is generally referred as cogeneration-plant produce both power and steam is installed to meet process plant requirements. Any change of demand in either power or steam would affect the other. In progressive process plants interconnection of units generating s ...

Learn MoreAUTHORS

R Somasundaram

The prestigious Robotic gallery is an iconic project, first ever of its kind in India. A world class facility to educate the people in the field of robotics and provide the young brains a platform to showcase their innovations. Built by the Gujarat Council of Science City, Department of Science ...

Learn MoreAUTHORS

Akshay Aggarwal

Energy cost is one of the significant contributors of production cost for most of the Industries. Hence, reduction in energy consumption electrical, thermal or in any other form always helps in business sustenance and growth. Moreover, as most of the energy is derived from fossil fuels, any red ...

Learn MoreAUTHORS

Bharat Yadav

Conventionally in most of the thermal power plants, ash from the Economiser (ECO) and Air Preheater (APH) hoppers will be evacuated in slurry form and mixed with the Bottom Ash (BA) which is also extracted in slurry form for further disposal. The ECO and APH ash will not be mixed with Fly Ash ( ...

Learn MoreAUTHORS

H Ramakrishna

Digital Engineering and its visual simulation capabilities make it possible to look, see, experience and construct. However, this is just scratching the surface when it comes to application of these tools to engineering design. New business models and service delivery options are being discover ...

Learn More

Time bound construction is essential for any project to optimise the cost and for quicker reverse cash flows. Construction simulation using 4D model enables effective planning of construction activities, identify the problems during construction and helps planners to troubleshoot. The sequences ...

Learn MoreSeptember 2015

By Nitin Gupta & T. K. Pal, Mechanical, TCE - The term 'Pinch Technology' is a new set of thermodynamically based methods that guarantee the design of heat exchanging networks with minimum energy levels. The equations are primarily based on the First Law and the direction of heat flow is determ ...

Learn More

By Sugata Bandyopadhyay, Instrumentation and Control, TCE - The concern for Global Warming and Climate change has already made a social impact on the planet earth and corporate strategy on mitigating plan needs to be adopted to restore ecological balance. While any economic growth is associated ...

Learn MoreAUTHORS

Sugata Bandyopadhyay

7 August 2015

Creating a better tomorrow is all about working closely with our clients, industry visionaries, policy makers, public and financial institutions. It is about leveraging our past experiences, our partnerships and our key assets, our employees, in the best possible manner. However to be able to d ...

Learn More Watch Video

International Conference on " Sustainable Clean Ganga Mission " was held on 12 December 2014 in Delhi, organized by Everything About Water. About 150 delegates attended the conference including the officials from Ministry of Water Resources and Ganga Rejuvenation, Upper Yamuna River Board, Emba ...

Learn MoreSeptember 2014

Since dredging takes place in a natural environment, uncertainty and therefore risk has to be accepted. This uncertainty can be reduced by undertaking modelling or additional studies but in such a complex system it can not be eliminated.

Learn MoreAUTHORS

Devdatta Bose

Group Sector Head

Mihir Parekh

Manager

Interruption of power supply and its impact can have serious repurcussions on the production cycle, facilities, equipment performance and human productivity. Power outage management is a critical area were technology solutions are required to mitigate the impact of power outages.

Learn MoreAUTHORS

Mr. S Jagadish

Ms. Priyanka Swain

Generally the belt conveyors in the Indian Industries are low speed type with belt speeds in the range of 2 to 3 mps. There are few installations with speeds up to 4.5 mps. Most of the conveyors existing in India are short distance conveyors with length up to 1 km. There are few installations i ...

Learn MoreAUTHORS

H Ramakrishna

In the fossil fuel fired power plants successful operation of once through steam generator technology and drive to achieve higher thermal efficiencies made possible for the development of supercritical steam generators. The paper discusses key factors to the success of supercritical technology.

Learn MoreAUTHORS

V Lakshmana Rao

R Raghavan

This paper covers the aspects of the wagon loading and unloading system currently in vogue in the Indian Industry. Generally the wagon loading systems are required in the mines and ports for loading the material into the wagons for further transportation to the process plants.

Learn MoreAUTHORS

H Ramakrishna

Managing the coal stockpiling system under environment-friendly conditions.

Learn MoreAUTHORS

H Ramakrishna

Information technology can effectively be used to virtually operate a number of power stations as a single unit to improve the plant performance, plant availability and cost of plant operation.

AUTHORS

Veena Ravishankar

A Bhattacharya

N Ramesh

The requirement of high efficiency in power generation and environmental considerations, installation of power plants with Circulating Fluidized Bed Combustion (CFBC) technology with lignite as main fuel would be a techno economically viable option. This paper outlines the present status of CFB ...

Learn MoreAUTHORS

S.Balasubramanian

K.Sudhindra

Surendra Bhat

© Tata Consulting Engineers Limited. All Rights Reserved | Site Credits:DV