In the second wave of COVID19, India witnessed a massive shortage of medical oxygen in hospitals. Even though oxygen used for industrial purposes was diverted for medical use, it was not enough to meet the increasing demand. Alternative modes of oxygen generation were required considering the colossal demand, especially at remote locations. Therefore, there was a need to look for additional sources through which oxygen could be generated quickly near the consumption point. A task force was set up at Tata Consulting Engineers (TCE) to study all possible options and work on engineering the fastest and best-suited option in the given circumstances.

Alternate and out of box solutions for storage and distribution of oxygen were investigated and published as the whitepaper, including conversion of CO2 fire extinguishers and LPG cylinders for medical oxygen service. All these methods involve statutory, legal and other approvals. They must be done with the proper involvement of government authorities. Adequate cleaning and colour coding of the cylinders are required for safety reasons. A governance mechanism involving government officials, PESO, Controller of Explosives, Fire Department, Medical Department (Min. of Health) and administrative authorities is also required for related compliances and approvals.

| 225+ Oxygen Plants Under Commissioning | 1,00,000+ Oxygen Concentrators Proposed for Manufacturing | 10,000+ MT/day Oxygen Impacted | Oxygen Enabled |

|---|---|---|---|

|

|

|

|

© Tata Consulting Engineers Limited. All Rights Reserved | Site Credits:DV

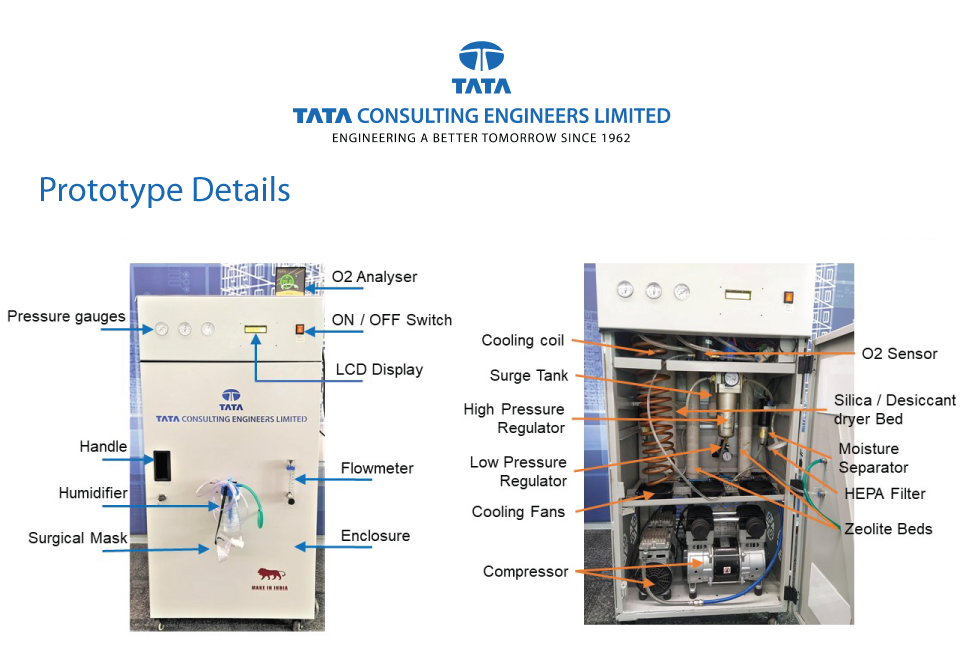

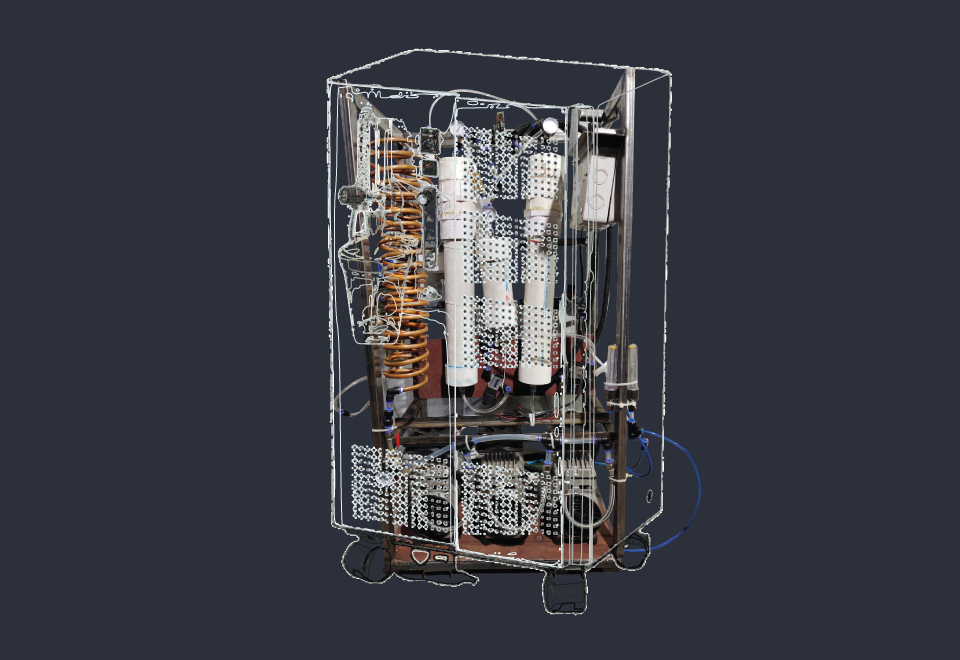

With COVID patients requiring between 5-20 LPM and keeping in mind the need for such devices in villages and interior parts of the country, TCE targeted the specification for up to 20 LPM designs. The prototype leveraging opensource design (www.oxikit.com) was accomplished in less than five (05) working days, with complete local parts as available in India (except Zeolite) and with benchmark results of 10-20 LPM of 90-95% oxygen concentration. Necessary design changes and process refinements were incorporated to ensure benchmark results under Indian conditions.

The TCE oxygen concentrator is based on proven PSA technology. It utilises a molecular sieve to adsorb gases and operate on the principle of rapid pressure swing adsorption of atmospheric nitrogen onto zeolite minerals at high pressure. PSA technology is a reliable and economical technique for small to mid-scale oxygen generation.

TCE prototype uses 3.2 Kg (7 pounds) Sodium Zeolite (0.4mm) to produce 20+ LPM of 92-95% Oxygen concentration. The design uses sodium Zeolite instead of Lithium-Zeolite keeping in mind the Indian ambient conditions, Zeolite availability, and to ensure a competitive price point advantage.

TCE calculated (pure material cost approx. INR 35-45k) and a benchmarked competitive price of INR 60k (+/-10%) for the specification designed, which can be further optimised based on mass manufacturing and bulk procurement strategies.

Even though the technology is proven, the device is sensitive to ambient conditions. Our study carefully assessed these aspects in the prototype test trails necessitating detailed review and modification in the opensource design to suit Indian requirements with locally available parts.

A new ‘Pressure Swing Adsorption (PSA) oxygen generation plant typically takes about eight months. PSA nitrogen plants were already installed and operational in many industries for industrial purposes. Given the COVID19 induced oxygen emergency, conversion of existing PSA nitrogen plants for oxygen production emerged as the most practical solution in the given situation.

The technology has been in existence since 1970, so workability was not an issue, the only concern was to see it working in front of us, and that too quickly as time was of essence.

The basic configuration and technology for both Nitrogen and Oxygen PSA units are similar. The significant difference being the adsorbent material. When the adsorbent material (activated carbon molecular sieve – CMS) of the nitrogen generating units is replaced (by Zeolites), the same unit that produced nitrogen becomes suitable for producing oxygen. The OEMs also confirmed this point. However, when such conversion is implemented, the nameplate capacity of the converted unit is reduced roughly to 25% of the original nitrogen generation capacity.

Once the feasibility was established, the team started contacting various OEM’s to get the desired timelines. Most OEM’s estimated three weeks for complete conversion of the units. The time indicated by OEMs is generally on the higher side because of the internal process of procurement of adsorbent beds and other equipment like oxygen filter, oxygen Analyser, some amount of piping changes, valves required, transport to site and then site installation, recommissioning etc. Work also involved flushing/cleaning/ purging the entire PSA Plant and making it suitable for medical oxygen production.

The R&D team of IITB offered the infrastructure available in their Cryogenic Lab. And they arranged for a suitable capacity compressor and dryers to integrate it with the demo unit of the nitrogen PSA unit. M/s. Spantech engineers carried out the activities for the conversion at their premises, including the supply of the molecular sieve adsorbent.

A new oxygen analyser was installed to check purity and compliance of medical oxygen requirements on the discharge pipeline from the Oxygen receiver. A fine filter was installed to filter out carryover of any particulate matter, dust etc., to suit medical oxygen specifications which can be further connected to the pressure regulator to meet the supply pressure requirements of medical oxygen.

The entire conversion took two days, and on the 3rd day, the skid was transported to the IITB Cryogenic lab and connected with the existing compressor and dryer. On day five, from the MOU signing, the skid was commissioned, and Oxygen with 93.5% purity generated at 25LPM with an input air temperature of 40 degrees C.

When the country was in urgent need of medical oxygen, the partnership of industries and academia demonstrated that the existing nitrogen PSA units could be quickly converted into medical oxygen generators.

The cylinders are the last mile connectivity between oxygen production facilities and the hospitals’ patient beds. Various alternative means for storing medical oxygen are being explored. Plenty of fire extinguishers are already available and in use across all the locations, be it offices, malls, theatres, residential complexes, etc. Since offices, malls, theatres are not in operation, and people are working from home, every city already has the availability of these storage devices.

These fire extinguishers can be used without worrying about fire safety as buildings are not occupied. Moreover, these are lightweight, easy to transport, and quick to fabricate in bulk. They can be potential candidates for converting and utilising for storing medical oxygen during emergencies like the COVID19 pandemic. Some essential considerations for checking the suitability of CO2 fire extinguisher cylinders as medical oxygen cylinders include confirming its pressure rating specifications, the material of construction, and the available cylinder’s capacity.

LPG cylinders are widely available, and the network of the supply chain has matured. As an alternative solution during emergencies, the use of LPG cylinders for medical oxygen can be explored. LPG cylinders are rated for a much lower pressure than conventional medical oxygen gas cylinders.

The suitability of basic materials of construction is reviewed. Irrespective of the pressure rating and/or materials suitability checks, it is vital to note that the LPG is a flammable fluid. It CAN NOT be directly used by filling oxygen into it. However, the lower pressure could result in lower residence times, which should not be a concern for exploring its suitability for medical oxygen.

It must be ensured that all LPG cylinders must be made hydrocarbon-free before filling oxygen. The use of new cylinders is highly recommended to avoid issues of internal corrosion. The cylinders must be cleaned appropriately, inertised, hydro tested before using for oxygen service. It is also recommended to install suitable filters in the oxygen supply line from the converted LPG cylinders.

To meet the COVID19 challenge requiring urgent strengthening of health infrastructure, Tata Consulting Engineers (TCE) and its subsidiary Ecofirst designed a ‘ready to implement’ modular health facility. Each module is equipped with air-conditioning, five beds and one toilet. This ready to use design can be implemented immediately as an extension of an existing hospital or a completely new COVID19 hospital anywhere in India. These modular units put together can expand to any number of beds, are self-sufficient, sustainable, and can be easily repurposed or dismantled in the future.

The design of these modular units incorporates inputs received from medical planners, COVID doctors, virologists, architects, HVAC and ventilation experts. Tata Consulting Engineers shared these designs freely with many implementing or donor agencies for immediate use.

A 30 Sqm. unit known as ‘Standard Tata Unit’ (STU) accommodates five beds along with one washroom. The unit’s design is such that it can be altered, responding to the varying site conditions and end requirements. The same modular unit can be tweaked to be used as separate units/modules as Isolation Wards, Quarantine Wards, and ICUs. These modules can be clustered together to work as full-fledged makeshift medical facilities during a shortage of healthcare facilities. Various construction technologies and materials were explored to best suit the unit such that it is easy to transport, zero wet construction, and installation can be done within a day with the help of less-skilled labour.

The design of STU Isolation and Quarantine wards aims to meet the immediate emergency requirements of various health facilities across cities in the short term and improve the efficiency of existing healthcare infrastructure in the long term. Though the STU has been tailored for pandemic use, however, the modularity of designs helps flexibility to use at any point in time, even after a pandemic. It can be quickly deployed in various country cities, promptly responding to treat and contain COVID19. Each unit works autonomously and can be expanded to create multiple modular configurations forming larger facilities. The STU is conceived as a ready-to-use solution adapting to the needs and capacity of local healthcare infrastructure.

While creating the prototypes and pilots, Tata Consulting Engineers (TCE) realised the acute shortage of a vital component, Zeolite, to convert PSA Nitrogen plants to produce Oxygen. The same is also required for installing new oxygen plants.

TCE partnered with Tata Chemical for the required sourcing of Zeolite from Europe. With the support of the Ministry of Commerce, PSA, DSIR & CSIR, we received GOI – IAF support for urgent airlifting of this critical resource to convert and install new oxygen plants.

With the support of Tata Chemicals and Central Pollution Control Board, TCE created a process of due diligence and project managed the allocation of this raw material to more than 65 plants, ensuring timely availability of the essential resource at an affordable price.

TCE teams are assisting various Central efforts, State Governments, Startups, NGOs and Hospitals on all of the above topics and are also providing consultancy for new PSA Oxygen plants, hospital oxygen infrastructure, pipelines and related checklists and audits. TCE has responded to more than 3000+ requests for information and support.

An engineering, feasibility and viability study was conducted on multiple ventilators, and a viable open source ventilator was identified. The learnings were shared with group entities for evaluation, and appropriate next steps were suggested for mass manufacturing related tie-ups.

Multiple Ventilator design were studied for feasibility under emergency conditions (No prototypes were created, only feasibility evaluations and recommendation made).

OpenSource Medtronics Ventilator was finally zeroed upon, and manufacturing firms were conveyed to explore tie-up and manufacturing.

As the COVID-19 pandemic posed newer medical challenges. Hospitals across the country face infrastructure challenges for increasing the Oxygen Generation and then ensuring the last mile connectivity of this oxygen. Tata Consulting Engineers (TCE) is consulting across various States, namely Rajasthan, Maharashtra, Uttar Pradesh, Odisha, Andhra Pradesh, Silvassa and Gujarat to help with the supply chain and capacity enhancement.

TCE is also helping various NGOs and hospitals including Tata Medical Centre for their Oxygen augmentation and readiness.

TCE along with its subsidiary has designed and distributed the designs for emergency Modular Units with Oxygen, AC and Medical support.

The office of the Principal Scientific Adviser to the Government announced ‘Project O2 for India’. The project has been initiated to ensure supply of critical raw materials such as zeolites, setting up of small oxygen plants, and manufacturing of compressors. The second wave of COVID-19 saw an increase in demand for medical oxygen in different parts of the country. This team has been setup to build a resilient oxygen network within the nation.

The manufacturing and supply consortium includes Bharat Electronics Limited (BEL); Tata Consulting Engineers (TCE); C-CAMP, Bengaluru; IIT Kanpur; IIT Delhi; IIT Bombay, IIT Hyderabad; IISER, Bhopal; Venture Center, Pune; and more than 40 MSMEs.