An Electronic Ear System is used to monitor the performance of grinding mill by measuring the mill sound. The sound generates sonic waves which may be captured by a sound sensitive device. This can be used to monitor the sound level generated by a grinding mill. With various loading depending on the feed inside the mill to be grinded, the utilization of grinding mechanism & empty space, the frequency of sound changes. This sound frequency can be used as an indication of load within the Mill. The operator can use the Electronic Ear to analyze the sound frequency spectrum and patterns, which can provide early warnings on the equipment status, e.g. warning related to the damage of costly liner or the sound trend toward an overload or under load condition which may interrupt production etc.

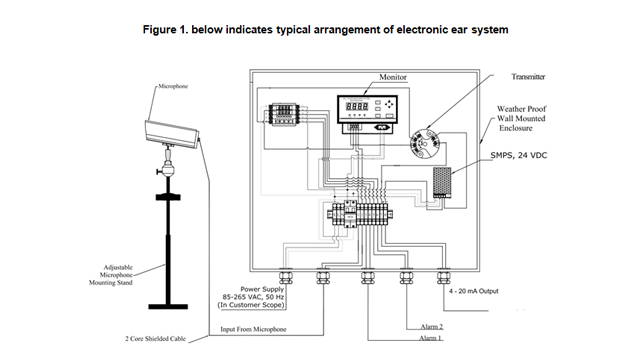

The microprocessor based Electronic Ear system consists of microphone and amplifier cum control unit. The microphone is to be installed as near as possible to the mill jacket. The microphone converts the sound into electrical energy and transmits it to the control unit. The control unit output of 4-20 mA signal which transmits the information on sound spectrum for inferring the loading of the mill. The control unit also generates alarms when mill noise spectrum analysis depicts operation of the mill above or below the preselected levels. These signal and alarms can be transmitted to the mill control room and can be used by operator to control the mill.

Based on the height of the grinding media inside, the mill causes a characteristic noise. In case of low material bed, there is high pitched grinding sound (i.e., high volume & high grinding sound frequency) and in case of high material bed, there is hollow grinding sound (i.e., low volume & low grinding sound frequency). This characteristic of grinding sound is used to develop an output signal proportional to the mill filling level, and can be used to control the mill feed.

The high pitched grinding sound warns an operator low material bed and impending liner damage and save cost of liner replacement and downtime. A hollow grinding sound warns the operator that the mill is potentially overloaded and production may interrupt. Advanced warning of impending problems can give the operator the opportunity to take appropriate and timely action. Maximum production and best operation are obtained at some intermediate mill load sound level.

In the present scenario the Electronic Ear System has become very essential non-contact type electronic device to help operator not only to control the performance of the mill from remote but also extends the life of the mill liner and grinding hammer / ball. Strategic locations of two or three microphones across the mill also enhance the performance and control the mill feed rate too.

TCE has recommended and implemented this system for monitoring and controlling the grinding mill performance in many projects engineered by TCE.

© Tata Consulting Engineers Limited. All Rights Reserved | Site Credits:DV