Generator step-up transformers

(GSUs) are the essential element of a power plant (thermal, nuclear, hydro and gas based). They are the critical link between the generating station and the transmission network. GSUs step-up the generating voltage level to the required evacuating transmission voltage level.

GSU being one of the expensive and critical electrical equipment in the power plant, selection of rating and configuration of GSUs is of paramount importance. In case of gas turbine based power plants, output of the gas turbine varies with the change in the site ambient temperature. Hence, GSU rating will be selected to fully evacuate the gas turbine output at site ambient temperatures from minimum to maximum.

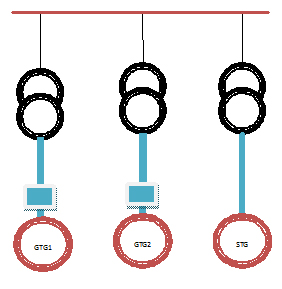

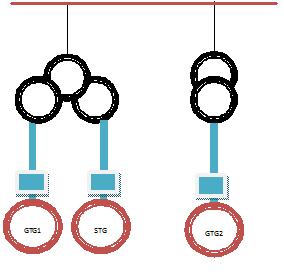

In Indian power industry, the most widely followed configuration for combined cycle plants is having dedicated generator transformer with two windings for each GTG and STG. This is a proven design and a default configuration adopted in most of the combined cycle power plants. Reliability in this configuration is higher as dedicated transformers are provided for each gas turbines and steam turbine generators. Failure of single transformer will result in outage of only that particular unit.

© Tata Consulting Engineers Limited. All Rights Reserved | Site Credits:DV