TCEL, Pune

Some of the reputed industries spray chemical fog for prevention of mosquitoes. In such cases the installed fire detection & alarm system within the factory/plant/warehouse, detects the smoke and indicates the smoke alarm on panel. The respective area hooter cum strobes start sounding the alarm/alert.

What is a chemical fog?

Chemical fog is an obscuring haze of dust or smoke.

FINDINGS OF ALARM:

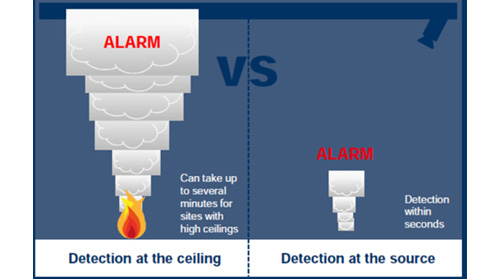

During chemical fogging, the Beam detectors installed above 7mtr elevation height and smoke detector (multi-sensor) installed below 7mtr elevation height detects alarm on main fire alarm panel.

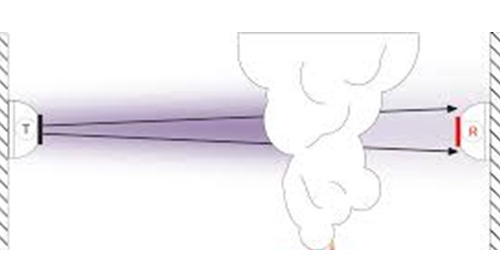

Beam Detector: Smoke cuts the IR rays between Transceivers & Reflector or between transmitter and receiver, which indicates the alarm condition on main fire alarm panel.

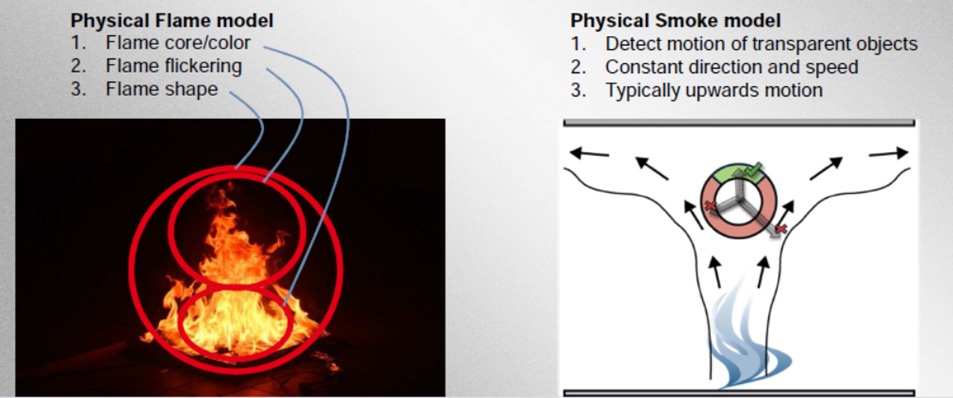

Multi sensor detector: Once smoke enters the detector, the multi sensor detector consisting of optical smoke and thermistor temperature sensors which gives a combined signal (Smoke & heat), also separate signal of heat detection to main control panel.

RESOLUTION

To resolve such issues below listed options can be useful:

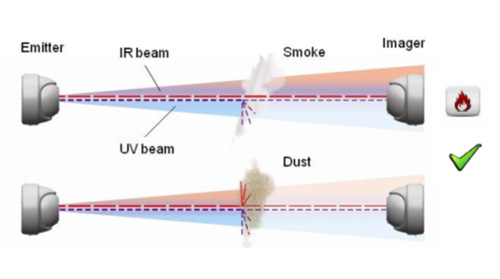

OSID is deemed to be a viable solution comprising of an Imager and seven numbers of emitters, which will replace the originally installed detection system. It delivers confirmed results, including unsurpassed resistance to reflections, condensation, dust, fog, steam and other obstacles like flying pigeon, also high tolerance to vibrations and any movement.

BENEFITS OF VSFD OVER OSID:

BENEFITS OF VSFD OVER OSID:

© Tata Consulting Engineers Limited. All Rights Reserved | Site Credits:DV