Safety Valve Noise

Noise in valves applies to oil and gas, chemicals & speciality chemicals, cement, steel and other process industries. Noise can cause damage to the pipes due to the high stress experienced. This is called Acoustic fatigue. High noise can cause damage to the ears. During the operation of safety valves, noise is generated due to pressure reduction at the orifice. Hence, the design of piping systems shall be able to withstand the acoustic fatigue & vibration caused due to the high noise, thereby avoiding any untoward incident.

The noise levels in Safety valves generally reach 160 dBA, which may occur only occasionally. However, as per API-521 & API EA 7301, the safe noise level at 30 mt (100 ft) is 115 dB(A), typical of the discharge location.

Health & Safety Engineers regularly analyse the noise levels, identify the source and apply mitigation measures such as

- Recommend low-noise valves instead.

- Reduce the flow through the valves or reduce the delta pressure across the valves by optimising the process.

- Installation of Acoustic Piping and

- Increasing the pipe thickness to reduce the valves’ stress and noise.

The noise from PSV operation, calculated based on API 521 Standard, is compared to the NORSOK L-002 of Standards Norway. A silencer is recommended if the noise calculated as per API 521 exceeds the allowable noise limit based on NORSOK.

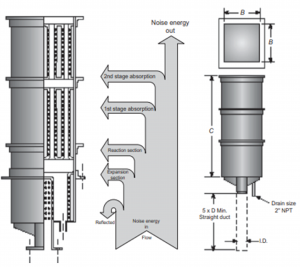

There are three components in the Silencers, namely Diffuser, Expansion Chamber and Absorption chamber.

Figure 1: Silencers Breaking the Noise in Stages

Noise attenuation is caused when the service passes through the silencer where part of the noise energy is:

- Reflected back

- Attenuated in the expansion section of the silencer

- Attenuated in the reaction chamber

- Attenuated in the absorptive sections

It may be better to use a silencer designed specifically for the system in operation. This can reduce the noise to a less harmful level.

Figure 2: Safety valve with Silencer

References

- Noise and Acoustic Fatigue Analysis in Valves (Case Study of Noise Analysis and Reduction for a 12″ × 10″ Pressure Safety Valve) | SpringerLink

- The Safety Relief valve Handbook Design and use of Process safety valves to ASME and International codes & Standards — Marc Hellemans

- Safety and reliability improvements of valves and actuators for the offshore oil and gas industry through optimised design by Karan Sotoodeh, Stavanger: University of Stavanger, 2021 (PhD thesis UiS, no. 573)